- Startseite

- 3D Printers and accessoires

- Formenbau & Gießen

- Silikon-Polykondensation

- Silikon-Polyaddition

- Dragon Skin™ Serie

- Ecoflex™ Serie

- Equinox™ Serie

- Mold Star™ Serie

- Rebound ™ Serie

- Smooth-Sil™ Serie

- Sorta Clear Serie - 'Wasserklare' Silikone

- Body-Double 'Hautsichere' Silikone

- Psycho Paint ™ Silikonfarbe Basis

- Platsil Gel & Deadener

- Rubber Glass

- Encapso™ K

- Solaris ™

- Soma Foama ™ - Silikonweichschaum

- EZ-Brush™ Vac Bag Silicone

- EZ-Spray Platinum Silicones

- Silicone Additives

- Silikone Mattierung & Glättungsmittel

- POLYURETHAN KAUTSCHUCK

- Alginat

- POLYURETHAN HARZ

- POLYURETHAN SCHAUM

- Epoxidharz

- Latex & Schaumlatex

- Mask Making Latex

- Mold Making Latex

- FormX Elastica

- Monstermakers Schaumlatex

- Monstermakers Mask making latex RD-407

- Monstermakers additives & Components

- Holden's Beschichtungs-/Tauchlatex Latex HX-200™

- Holden's HX- Body Latex™ Brushable

- Holden's Mold Making Latex HX-80™

- Holden's Brushable Mold Making Latex HX-974™

- Holden's Mask Making Latex - Pourable HX-407™

- Holden's Mask Making Latex - Brushable HX-807™

- Holden's HX-Cosmetic Latex™

- Holden's Frisket Mask Latex

- Holden's HX-Injection Medium™

- Latex Accessories

- Latex Pigmente

- Latex Paint

- Latex Thickener

- Polyester

- Gips & Zement

- AcrylCast

- Prince August

- Modellieren

- Jesmonite Acryl Systeme

- Buddy Rhodes Beton Systeme

- Additive

- Versiegler & Trennmittel

- Pigments

- Jesmonite Pigments

- Pure Pigments

- Ultra Fine Pigments

- SilcPig® Silikonpigmente

- Glow Worm™

- Cryptolyte Pigmente

- Silc Pig™ Electric

- Siltone Silikonpigmente

- SilTone Kits

- Silicone Pigments - FuseFX Coloring System

- Silicone Coloring System S.A.M

- Key Pigments für Silicone

- Kryolan Flock Faser

- Latex Pigments

- Polyester Pigment

- UVO Pigmente

- SO-Strong Pigmente

- Ignite

- Real Metal Powders 2

- Cast Magic™ Powders

- Faux Metal Powders 2

- Farbe

- Maker Pro Paint™

- Maker Pro Paint™ Metallics

- Maker Pro Paint™ Fluorescent

- Vallejo Acrylfarbe

- Vallego Acrylic Metalfarbe

- Maker Pro Paint Additive

- Vallejo Acrylic Mud

- Vallejo Primers and Laquer

- Psycho Paint ™ Silikonfarbe Basis

- Latexfarbe

- Latex Paint Base

- FFX LY-series paints

- FFX F-series paint

- FFX M-series paints

- jesmonite paint

- Füllmittel und Veredelung

- Lösungsmittel & Verdünner

- Klebstoffe

- Werkzeuge

- Grime & Maske

- Rubber Mask Grease Paint

- Skin Illustrator Paletten

- Skin Illustrator Liquid

- FleshTone 60ml

- FleshTone 120ml

- Dark FleshTone 60ml

- Dark FleshTone 120ml

- FX 60ml

- FX 120ml

- FX 240ml

- Complexion 60ml

- Complexion 120ml

- Alchemy 60ml

- Alchemy 120ml

- Grunge 60ml

- Grunge 120ml

- Grunge 240ml

- Mardi Gras Liquids 60ml

- Mardi Gras Liquids 120ml

- Necromania 60ml

- Mekash Colors 60ml

- Clear Gloss 60ml & 120ml

- Glo-Worm 60ml & 120ml

- Tattoo Classic 60ml & 120ml

- Sunburn

- Alphabetical all

- Skin Illustrator Singles

- Skin Illustrator Glazing Gel (Glacierungs Gel)

- Skin Illustrator Glazing Spray (Glacierungs Spray)

- Skin Illustrator Concentrates

- Skin Illustrator Mouth FX

- Allied FX (Blue Bird)

- RipperFX Palettes

- Stacolor Paletten

- PAX Paints Thomas Suprenant

- MaqPro Farde Palettes

- Tattoo Sheets

- MaqPro Make-Up Mixer

- MaqPro Creamy

- MaqPro Bruise Gel

- Grime Pinsel

- Old Age Stipple

- Stamps & Molds

- Sponges and Applicators

- Head Armatures

- FormX Tools

- Kryolan Make-Up

- Ausrüstung

- Spezial Effekte

- Prosthetische Materialien

- Marken

- FormX Academy

- Anwendungen

- Literatur

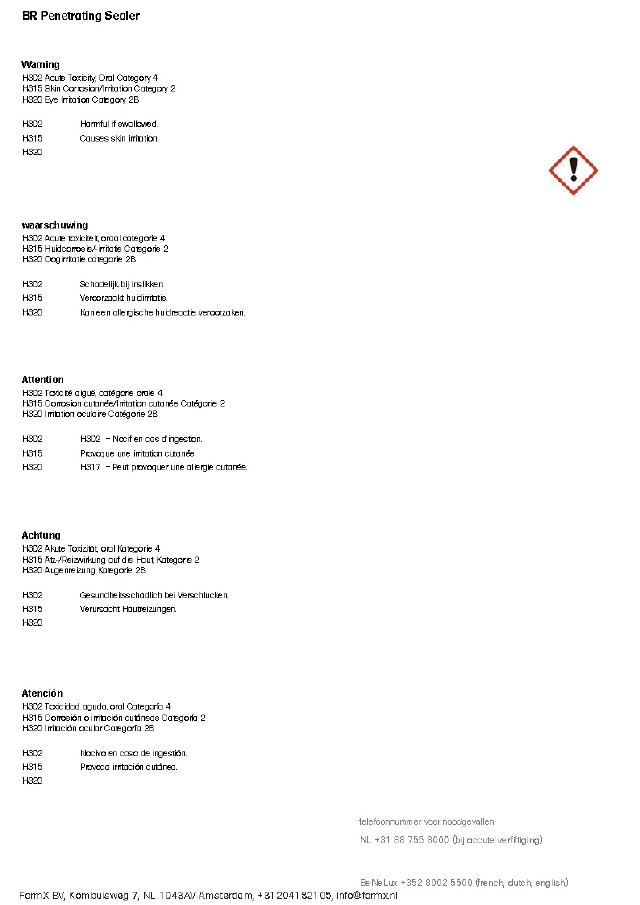

Penetrating Sealer /1 lt

- Lesen Sie das Sicherheitsinformationsetikett. Klicken Sie auf das Bild.

- Read the safety information label. Click on the image

- Lea la etiqueta de información de seguridad. Haga clic en la imagen

- Lisez les informations de sécurité cliquez sur l'image

- Lees het veiligheidsinformatie label. Klik op de afbeelding.

Aktion war erfolgreich

Das hat leider nicht geklappt.

Application Guide

Concrete Surface Preparation

Preparing the concrete surface before sealing is an important first step to ensure success with any sealer. The concrete must meet three conditions before starting with the sealer application:

• It should be properly cured.

• It should be properly processed.

• It should be clean and dry.

Curing

Standard practice is to allow the concrete to cure for 5-7 days after casting, adhering to good concrete curing practices. This ensures the cement matrixis maturing and the internal moisture levels have been reduced to low levels.For some concrete mixes this happens in a few days, for others it will take longer. You will need to set the time between casting and sealing based on the habits of the concrete you are working with. With Buddy Rhodes mixes, 5 days following casting is a good start, although more time should be given during cooler periods, and more time isalways better if you have time to give. For best results, let your concrete cure for at least 7 days.

Processing

The surface of the bare concrete should be processed to a visually matte finish, with a profile, or "tooth,"prior to sealing. This ensures the sealer develops a good mechanical bond with the surface. The rougher the

surface is, the better the sealer will adhere. Profiling also removes residual material or contaminants that wouldinterfere with forming a good bond. Wax and form release agents routinely transfer to the surface of the

concrete during casting, and these must be removed before sealing.

There are several ways to profile concrete surfaces. Acid Etching, Wet Sanding and Dry Sanding are three goodoptions, described below.

• Acid Etching- Acid etching provides a "tooth" for the sealer and dissolves any weak material in the substrate that may prohibit sealer from fully penetrating and adhering. Etching is most often performed on cream

finishes, or concrete that’s left untouched after it is demolded. Keep in mind acid etching mainly affectsthe cement paste, and will not change the surface of exposed glass, tile, or exposed stone such as quartz or granite. Etching may not entirely remove surface residue like wax or form release agents. For that werecommend light scrubbing with a non-woven abrasive pad. Muriatic acid substitutes are not recommendedas these types of acids can cause inconsistent reactions with the sealer. After acid etching, rinse well withclean water to remove any acid residue.

• Wet Polishing or Sanding - A popular and easy way to lightly work the surface without exposing sand grains is to hand-sand the surface using Buddy Rhodes hand pads. Use a 400-grit hand pad, as coarser grit can

leave scratches and can be too aggressive. The hand pads should always be used wet to prevent scratchingthe concrete surface. They're a great way to remove surface residue and to lightly smooth the concrete’s

surface. A wet-sanded surface can be etched to further enhance the microscopic tooth. When polishing alarger area or to remove material faster and efficiently, a pneumatic or electric polisher could be used.

• Dry Sanding- A method of opening the surface of the concrete or smoothing the surface of the concretewith processing methods that do not depend on the use of water. These methods include using the BR hand

pads dry, or using mechanical equipment such as orbital sanders or rotary polishers with dry diamonds pads.All tooling should be attached to vacuum equipment to control any dust that may occur during the surface

processing

Cleaning & Drying

The concrete surface should be cleaned after it has been profiled, since etching or sanding concrete creates very fine residue that must be removed before sealing. Non-woven abrasive pads can be used to remove the

fine residue. Rinse well with clean water. After cleaning, allow the concrete to fully dry prior to applying sealer. Dry concrete lets the sealer penetrate into the concrete, whereas wet, damp or barely dry concrete does not. A good rule of thumb is to wait a minimum of 12 hours for the concrete to dry following total saturation. Cooler shop temperatures will slow evaporation, so if the temperature is below 70°F/21°C, give the concrete more

time to dry out. When in doubt, wait 24 hours.

Environment

The Buddy Rhodes Sealing System should be applied at normal room temperature and humidity, and care should be taken to minimize airborne dust. Air and surface temperature should be between 10°C and 26.7°C

for 24 hours following application.

Tools and Materials Required for Sealer Application

• Microfiber Sponges

• Foam Rollers

• Microfiber Cloths

Application of Penetrating Sealer

The Buddy Rhodes Penetrating Sealer can be applied with microfiber cloths or sponges, or with a foam roller. Applya single, uniform coat and allow to dry completely before moving on to the next step, which usually takes about anhour depending on conditions. Do not apply in direct sunlight when temperature exceeds 26.7°C. Cleanup when wet with fresh water.

Application of Satin Sealer

The Buddy Rhodes Satin Sealer is applied using microfiber cloths, sponges, or a foam roller. Apply several thin, form layers, allowing material to dry between each coat, which usually takes an hour depending on conditions.Test each layer by sprinkling a small amount of water on the sealed surface. If water penetration occurs or if water does not bead up on the surface, apply an additional layer. This test should be performed after each coat. Do not apply in direct sunlight when temperature exceeds 27°C. Cleanup when wet with fresh water. If dried, use lacquer thinner or xylene.

Application of Beeswax

Apply with a soft microfiber cloth or sponge. Buff with a soft cloth or mechanical buffer to an even sheen.

Care and Maintenance

• Wipe up spills as they occur.

• Clean regularly with recommended non-abrasive cleaners such as Clorox Kitchen Cleaner or Windex Vinegar MultiSurface Cleaner

• Soft abrasive cleaning sponges can be used such as Scotch-Brite Non-Scratch Scrub Sponges

• Never used a sealed countertop as a cutting board.

• Always use coasters or felt pads below anything with sharp edges.

• Avoid leaving potted plants or objects that will maintain wet contact in one spot with the counters for extended

periods of time.

• Reapply beeswax once per month or as necessary to maintain protection and appearance.

Hilfe bei der Auswahl

Produkte nach Anwendung sortiert, z. B.:Lifecasting, Bildhauerei, Gießen, Special FX Make-up, Zahnprothesen Special FX, Studium.

naviguer par application

Ces produits sont classés par application telles que, le moulage du corps humain, le moulage, les tirages, les produits transparents, la restoration, le prototypage, etc...

Ihr One-Stop-Shop für 3D-Modelling-Materialien